A medical one-way valve is a device used to control the one-way flow of fluids, usually consisting of the following parts:

1. Valve body: usually cylindrical or spherical, with a valve inside to control the flow direction of the fluid.

2. Valve: usually a spring-type or diaphragm design, which can automatically open or close according to the pressure of the fluid to ensure that the fluid can only flow in one direction.

3. Connector: used to connect the valve body and the pipeline to ensure that the valve can be properly installed in the fluid pipeline.

These accessories can be selected and combined according to different medical devices and usage scenarios to ensure that the one-way valve can work properly and meet treatment needs. When choosing medical one-way valves and accessories, it is recommended to consult professional medical device suppliers or medical device manufacturers to ensure the quality and applicability of the products.

The use scenarios of medical one-way valves include but are not limited to the following aspects:

1. Respiratory apparatus: In respiratory apparatus, one-way valves can be used to control the flow direction of respiratory gases to ensure that gases can only flow into or out of the patient's respiratory system in one direction.

2. Infusion equipment: In infusion equipment, one-way valves can be used to control the flow direction of liquid drugs to prevent backflow of liquid in the infusion pipeline.

3. Venous catheters: In venous catheters, one-way valves can be used to control the flow direction of intravenous fluids to prevent backflow of intravenous fluids causing infection or other complications.

Medical one-way valves play a very important role in medical devices. They can ensure that fluids flow in the correct direction in medical devices and ensure the effectiveness and safety of treatment.

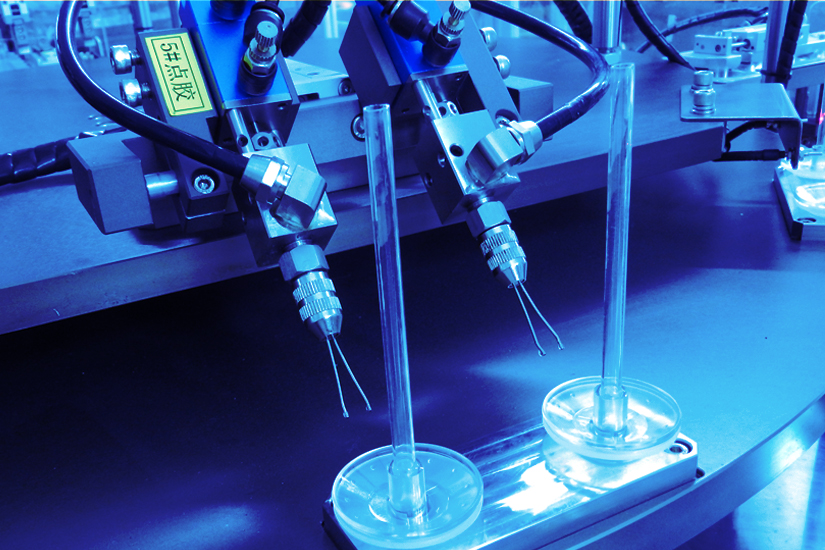

After the one-way valve is assembled with automated equipment, the following measures are usually required to ensure quality and production capacity:

1. Quality control system: Establish a complete quality control system, including quality management measures for the entire process from raw material procurement, production process control to finished product inspection. Ensure that each link meets specifications and standards to improve product consistency and stability.

2. Automated testing equipment: Introduce automated testing equipment to monitor and test the key parameters of the one-way valve online, promptly detect and handle abnormal conditions in the production process, and ensure that product quality meets requirements.

3. Data analysis and feedback: Through data collection and analysis, real-time monitoring of key indicators in the production process, timely adjustment of production parameters, and optimization of production efficiency and product quality.

4. Training and management: Provide professional training for production operators to improve their skills and quality awareness, and ensure standardized operation. At the same time, establish a strict production management system to supervise and manage the production process to ensure the smooth implementation of the production plan.

5. Fault prevention and maintenance: Regularly maintain and maintain automated equipment to prevent equipment failures and ensure continuous and stable production.

At the same time, establish a fault handling mechanism to handle equipment failures in a timely manner and reduce production interruption time. Through the comprehensive application of the above measures, the product quality and production capacity of the one-way valve after assembly with automated equipment can be effectively guaranteed, and the production efficiency and product quality level can be improved.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

中文

中文

English

English