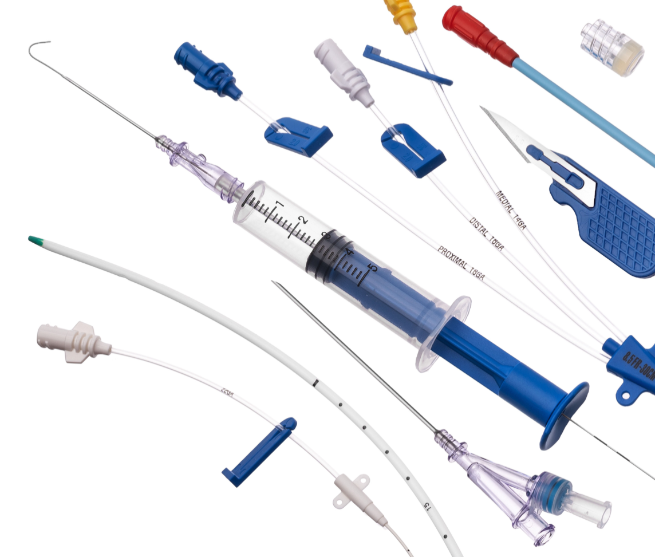

The Y-type puncture needle is a medical device, usually used for blood collection or infusion. Its product structure usually includes a needle tube with a Y-shaped head, a connecting tube and a connector.

The use scenarios of the Y-type puncture needle include but are not limited to the following aspects: 1. Blood collection: The Y-type puncture needle can be used to collect blood samples from patients for various blood tests. 2. Infusion: Medical staff can use the Y-type puncture needle for infusion operations to deliver drugs or fluids to the patient. 3. Venous blood collection: The Y-type puncture needle can be used for venous blood collection, such as during surgery or when continuous monitoring of patient blood indicators is required. 4. Hemodialysis: In dialysis treatment, the Y-type puncture needle is also an indispensable device for connecting the dialysis machine and the patient's blood vessels.

In general, the Y-type puncture needle has a wide range of applications in the medical field, which can help medical staff perform a variety of medical operations to ensure that patients receive accurate treatment and monitoring.

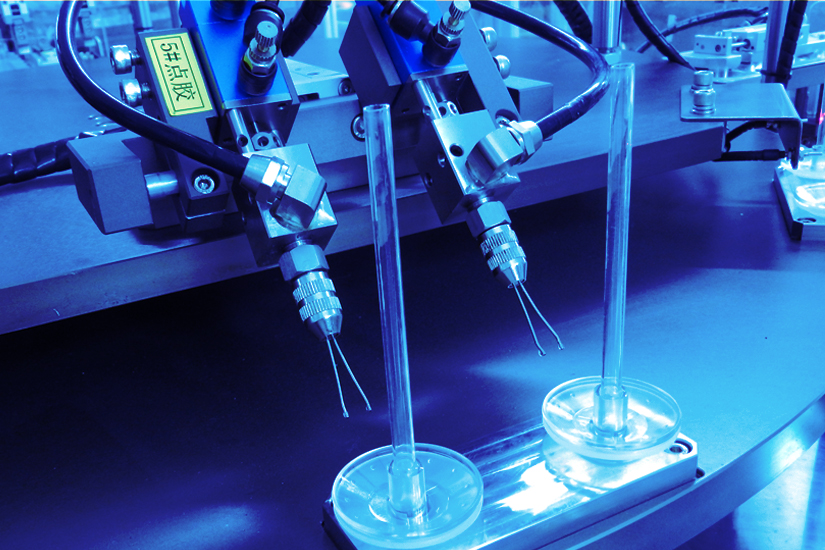

The benefits of using automated assembly for Y-type puncture needles include: 1. Improve production efficiency: Automated assembly can greatly improve the production efficiency of Y-type puncture needles, reduce labor costs and production time, and thus improve production efficiency. 2. Improve product quality: Automated assembly can reduce the impact of human factors on product quality, ensure that each component of the Y-type puncture needle can be assembled according to standard specifications, and improve product quality stability. 3. Reduce error rate: Automated assembly can reduce the error rate in human operation, improve the assembly accuracy of the Y-type puncture needle, and reduce the product defect rate. 4. Save costs: Although the investment cost of automated equipment is high, in the long run, automated assembly can save labor costs, reduce scrap rates, and thus reduce overall production costs.

Customers' evaluation of the use of automated assembly for Y-type puncture needles is usually positive because they can benefit from more efficient, stable, and high-quality products. The benefits of automated assembly not only improve the competitiveness of products, but also enhance customer trust and satisfaction with products.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

中文

中文

English

English