The water meter movement is the core component of the water meter, which is used to measure water consumption and record data. It usually consists of the following main components:

1. Spring diaphragm: used to measure the change of water flow and convert it into mechanical movement.

2. Gear system: convert the movement of the spring diaphragm into rotational motion, and record the water consumption by counting the gears.

3. Sensor: used to record mechanical motion and transmit data to the water meter display panel or other terminal devices.

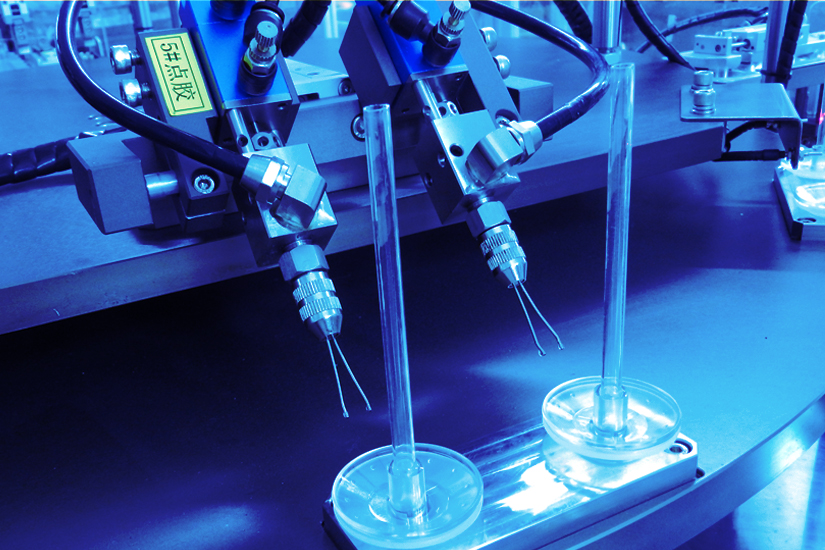

Manufacturers usually use advanced automation equipment for production operations. These equipment can accurately and efficiently complete various processing procedures, such as cutting of spring diaphragms, manufacturing and assembly of gears, etc. Automated production greatly improves production efficiency and can ensure the stability and consistency of product quality.

After using automation equipment, the water meter movement production process will bring the following changes:

1. Improve production efficiency: Automation equipment can achieve fast and continuous production, greatly saving production time and labor costs.

2. Improve product quality: Automation equipment can accurately control the processing parameters of each process, avoid the influence of human factors on product quality, and effectively reduce the defect rate.

3. Reduce production costs: Automated equipment can complete a large number of production tasks with lower manpower input, while reducing the scrap rate, thereby reducing production costs.

4. Improve production flexibility: Automated equipment can be quickly adjusted and changed according to demand, adapting to the production of water meter movements of different models and specifications, and improving the flexibility and adaptability of the production line.

Using automated equipment for water meter movement production will bring higher production efficiency, more stable product quality and lower production costs, meet market demand and maintain competitive advantage.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

中文

中文

English

English