The washing machine tractor is one of the important household appliance accessories of the washing machine, which is used to drive and control the rotation of the washing drum. Its accessories include the following parts: 1. Motor: The motor is the power source that drives the washing machine tractor to operate, usually using an AC motor or a DC brushless motor. 2. Reducer: The reducer is a device that converts the high-speed rotation output of the motor into a suitable low-speed and high-torque output. It achieves the deceleration effect through a gear assembly. 3. Gear assembly: The gear assembly consists of multiple gears and shafts and other components, which are used to transmit and adjust the rotational force of the motor. It usually includes driving gears, driven gears and bearings.

In the traditional production of washing machines, there are many pain points in the assembly production process of manufacturers: 1. High manual operation intensity: The traditional washing machine production line requires a lot of manual operation, such as installing gear assemblies, connecting motors, etc., which has high work intensity and is prone to fatigue and errors. 2. Complex assembly process: The assembly of the washing machine tractor involves the precise matching and installation sequence of multiple parts, which requires experienced workers to operate, takes a long time and has certain human errors.

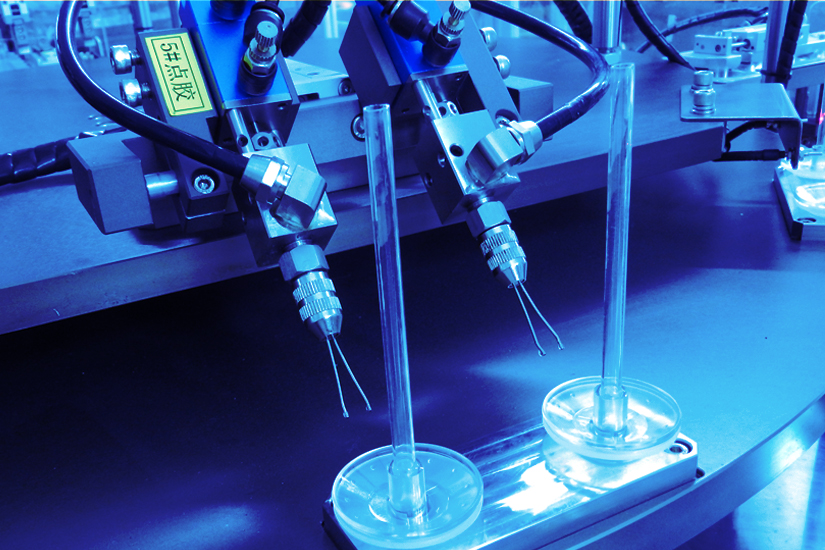

After the manufacturer introduced the traction automatic assembly line, the production efficiency was improved: the automatic assembly line can realize the rapid assembly of the washing machine traction, reduce the manual operation time, and improve the production efficiency and capacity. Improve product quality: the automation equipment has high precision and stability, which can reduce human errors and improve the installation quality and consistency of gear components. Reduce costs: through the investment of automation equipment, manual operation and material waste can be reduced, thereby reducing production costs.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

中文

中文

English

English