Timing function and sensor technology are indispensable functions in all household appliances at present. Microwave ovens, washing machines, pressure cookers, electric ovens, dehydrators, dishwashers, disinfection cabinets, electric fans and other household appliances must use timing functions. According to the structure, the timers used in household appliances can be roughly divided into mechanical timers and electronic timers. The structure of mechanical timers is similar to that of clocks. It is composed of a large number of gear systems meshing with each other, and the original power is springs or motors.

Qianyan Intelligent's research and development and application of mechanical timer automation equipment began in 2015. It started with the first rice cooker timer motor assembly machine for Jiangsu and Zhejiang customers, and then the rice cooker timer automatic assembly line, dehydration timer automatic assembly line, motor left and right stator assembly machine, conversion switch automatic assembly line, microwave oven grill timer motor assembly machine, 15-minute timer assembly line, tractor assembly line, microwave oven grill timer automatic assembly line, oven timer assembly line, etc., and also involved the assembly and detection of each gear component inside.

1. Domestic timer production supply chain

Currently, domestic timer manufacturers are mainly concentrated in Jiangsu, Zhejiang and Guangdong, and mainly supply to home appliance manufacturers such as Midea, Sanyo, Philips, Galanz, Donlim, Whirlpool, Royalstar, Joyoung, Rongsheng, and Macro.

2. Disadvantages of traditional production methods of timer companies

Compared with five years ago, most timer manufacturers currently use automated equipment. However, it is inevitable that some companies or some product processes are still carried out in the traditional way, that is, manual plus belt line. Where manual labor is required, product consistency cannot be fully guaranteed and quality is unstable. When manual labor is performed, there is too much arbitrariness; skilled workers and interns intersperse operations, and the process is difficult to control. Especially before the Spring Festival every year, the employee turnover is too large, which puts great pressure on the timely delivery of orders.

3. Implementation of timer assembly automation

Through industry investigations, Qianyan Intelligent Company understands that many processes in the manual assembly of timers can be completed in an automated way. Combined with the actual experience of the past five years, we will increase communication and exchanges with customers in the timer industry, strive for win-win cooperation through equipment upgrades and optimization and cost control, and enable customers' production factories to realize Industry 4.0 as soon as possible.

4. Advantages of timer automation equipment

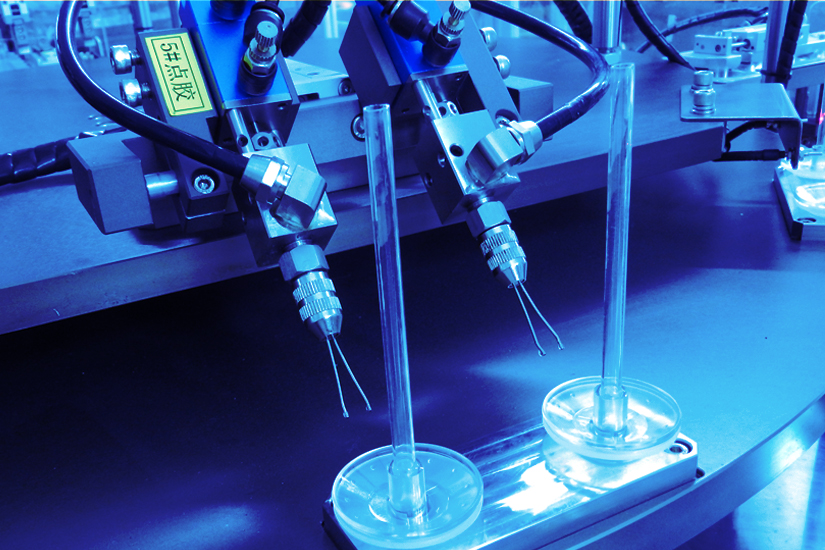

The project will completely replace the traditional manual operation form. All materials are automatically arranged in a certain direction by the vibration plate, and the manipulator automatically grabs and puts them into the fixture of the disc mechanism or linear mechanism to realize automatic assembly. The entire assembly process includes adding lubricating oil, butter or grease, screwing, wire cutting, wire stripping, testing and other links.

Enterprises that have introduced highly intelligent equipment have quickly seized the industry's high ground and become modern factories. The significance behind it is not limited to product quality assurance, stable production capacity, and higher industry competitiveness. It is to better practice Made in China 2025, become a characteristic local enterprise, better drive local economic development and construction, and contribute to the great rejuvenation of the nation.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

中文

中文

English

English