In a closed system, the intelligent plasma collection system collects whole blood into a centrifuge cup through a blood pump. The centrifuge cup rotates at high speed in the centrifuge to separate blood components, obtain high-quality plasma, and ensure that other components of the blood can be safely returned to the donor without damage.

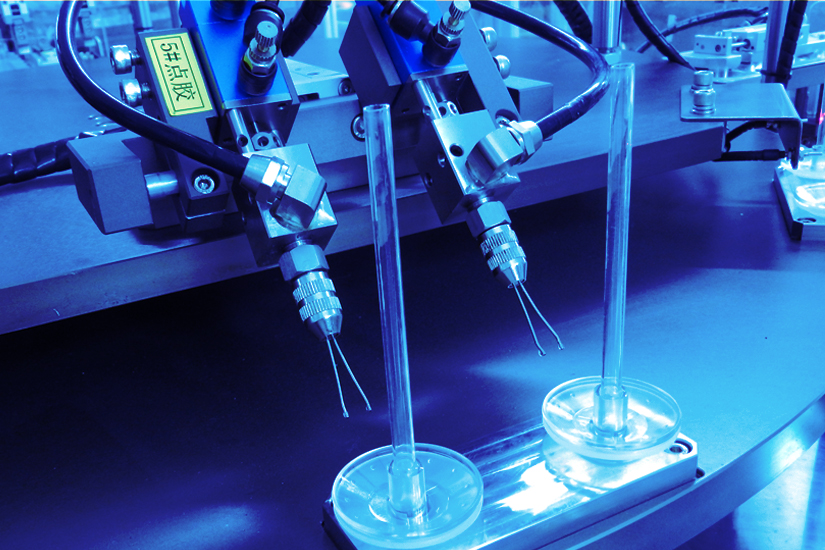

The more important role of the plasma bag test tube is to allow the collected blood to enter the test tube directly, and the medical staff will centrifuge the plasma in the test tube for blood testing. That is, there is no need to extract plasma from the blood bag for testing, saving operation time, while improving safety and preventing the transmission of hepatitis and HIV. The plasma bag test tube has the characteristics of sealing, cleanliness and safety. In order to ensure such high standards in the production process, manual operations are inevitably missed, so the advantages of automation are reflected.

The test tube assembly developed and manufactured by Qianyan Intelligent can assemble 2,400 products in one hour and 50,000 per day. The assembly speed is 300% higher than that of manual work. The product consistency is strong, which ensures the production characteristics of the test tube product and reduces the risk of product defective rate and manual operation contamination of products.

Our company also focuses on automation equipment for other consumables of intelligent plasma collection systems, such as plasma bags, plasma separation cups, etc. Friends with relevant needs are welcome to communicate!

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

中文

中文

English

English