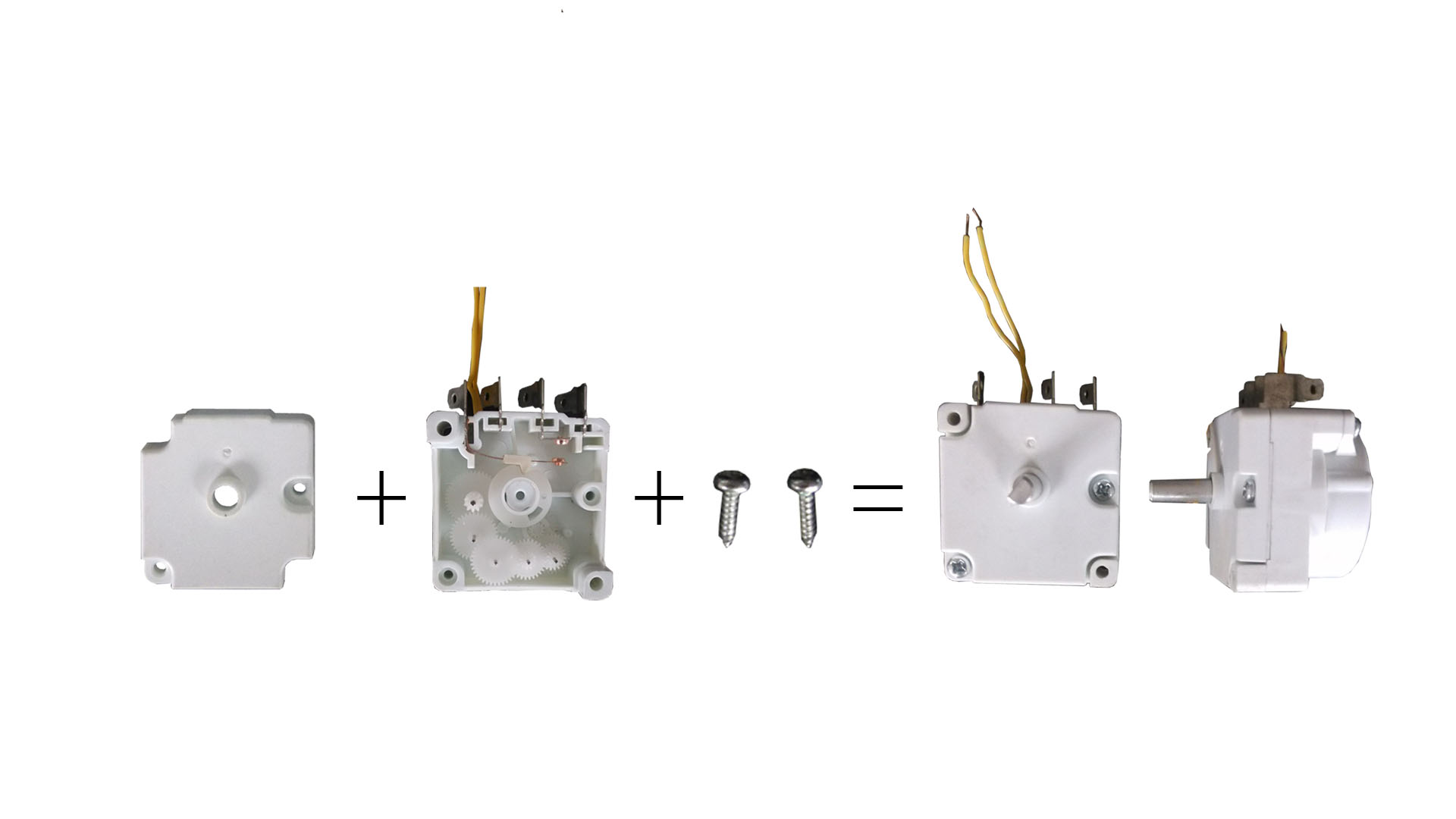

Home appliance parts automation - Rice cooker timer assembly line >>>

Process: This equipment is used to automatically complete the assembly of the timer. The entire assembly line consists of 7 devices, namely: motor assembly → pin coding → gear glue locking screws → contact plug → gear glue assembly A → gear assembly B → cover plate locking screws, wire stripping → automatic unloading. The assembly is precise and easy to operate, which improves production efficiency and ensures product quality.

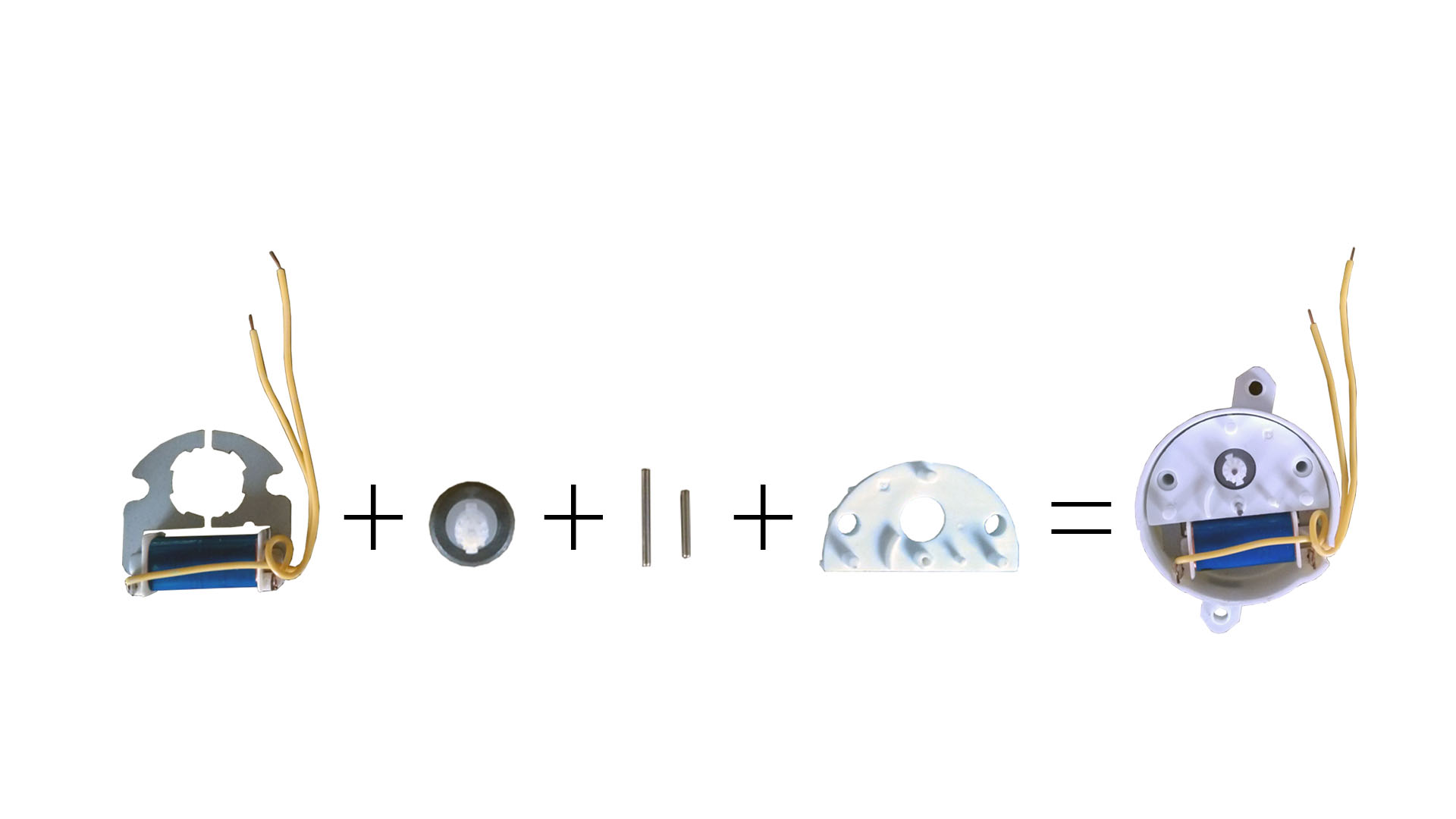

1.Motor assembly machine | 2、Pin coding machine |

|---|---|

Accessories map The process includes: upper shell, upper stator, shell ugly shaft, upper rotor, upper middle clamping plate, middle clamping plate shaft insertion, and motor cutting. |

Accessories map Including processes: upper base, gear shaft insertion, motor housing coding, automatic unloading. |

|

|

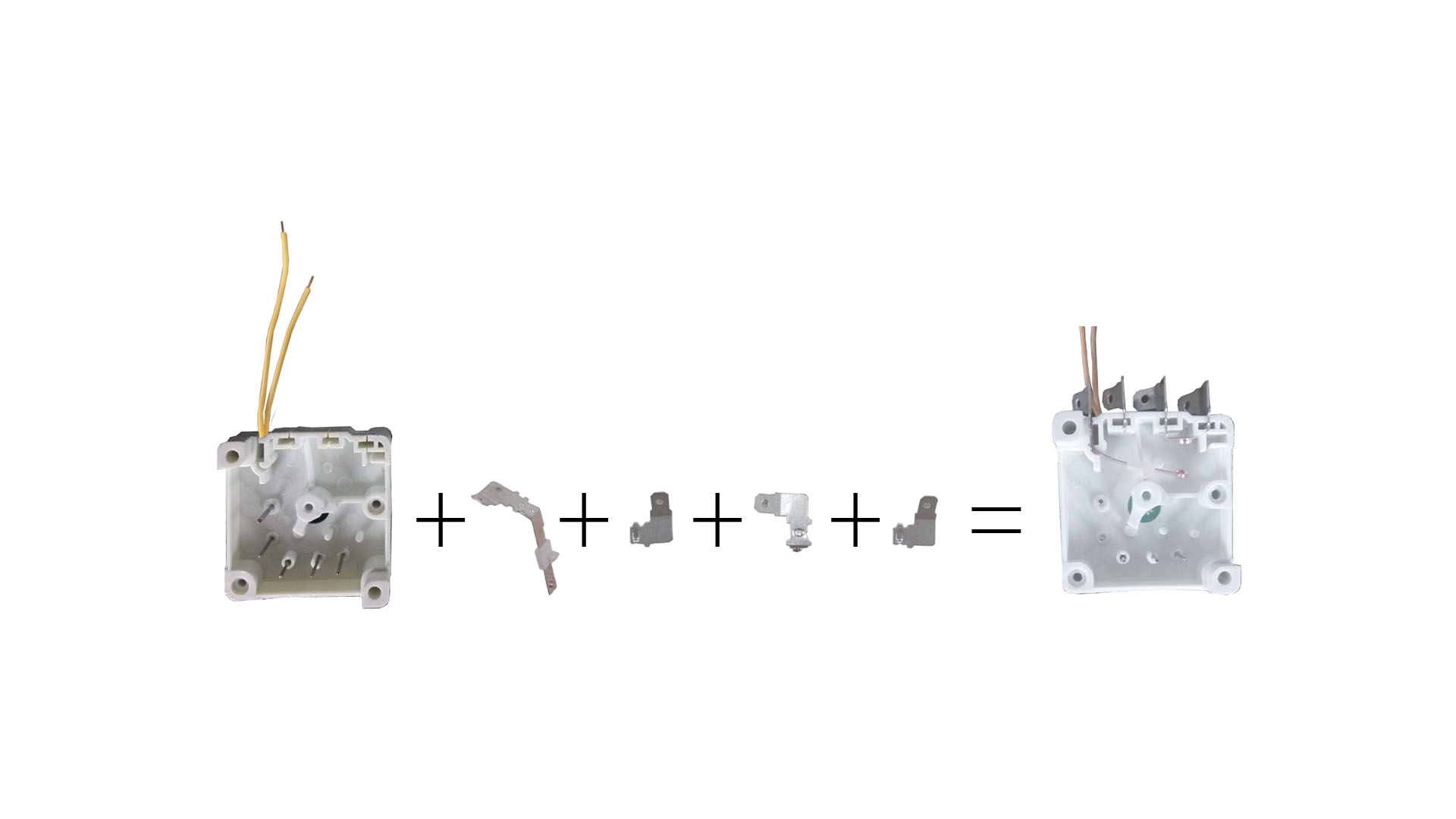

3、Motor case assembly machine | 4.Box spring inserting machine |

Accessories map The process includes: output gear installation, rotor output gear oiling, manual outer cover placement, screwing, and automatic unloading.

|

Accessories map Including steps: put on the base, install the reeds in sequence |

|

|

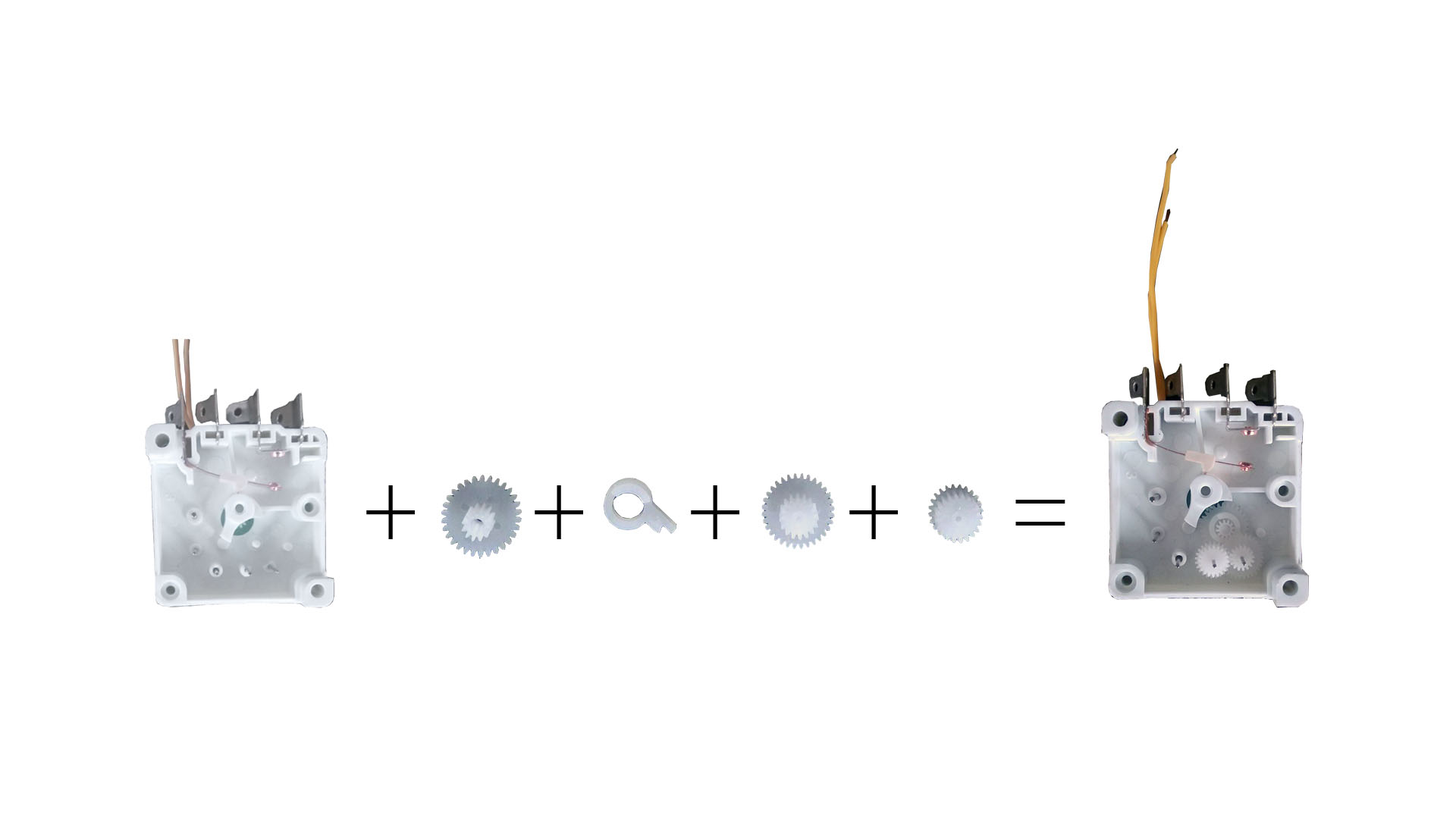

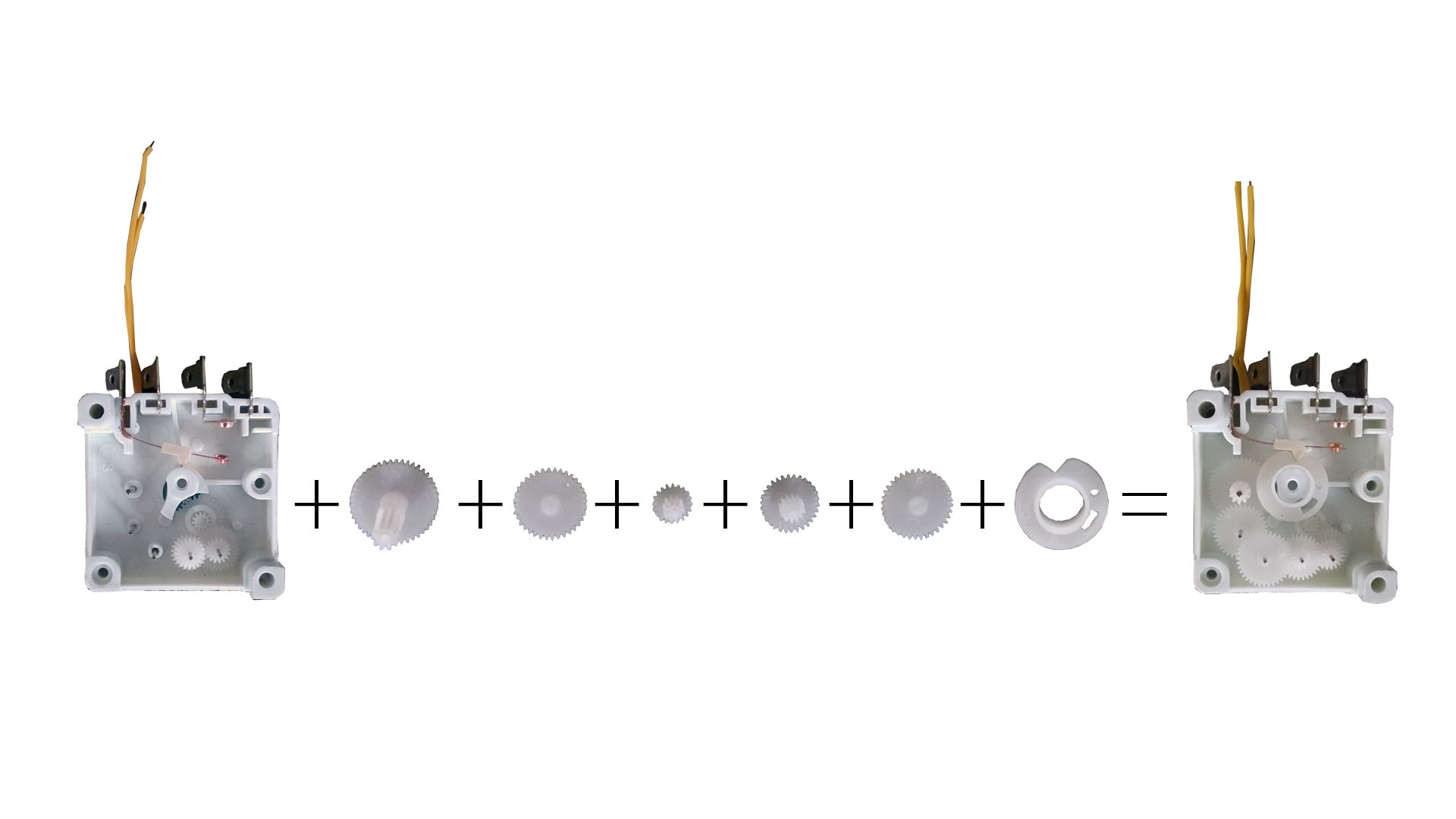

5.Gear assembly machine A | 6.Gear assembly machine B |

Accessories map The process includes: automatic loading, placing gear 1, placing directional sheet, oiling the directional sheet, placing gear 2, placing gear 3, and automatic unloading.

|

Accessories map The process includes: automatic loading, loading gear 1, loading gear 2, loading gear 3, loading gear 5, loading time wheel, and automatic unloading. |

|

|

7.Lock cover plate stripping machine | |

Accessories map Including processes: automatic loading, cover plate installation, screw 1, screw 2, automatic wire stripping, automatic unloading.

| |

- Machine related parameters

| NO | Project Name | Parameters | Notes |

| 1 | Assembly cycle | 4 seconds/time | 900pcs/H |

| 2 | Assembly tooling | Specialized | |

| 3 | Assembly accuracy | Error less than 0.05MM | No damage to the product during assembly |

| 4 | Monitoring mode | Multiple monitoring modes | Parameter setting, height value, position value |

| 5 | Control mode | Automatic/manual conversion | All actions of the equipment should have automatic and manual mode selection functions, and the operation panel and installation position should be reasonably designed. |

| 6 | Operation mode | Human-machine cooperation | Some workstations require manual operation |

| 7 | Equipment dimensions | (L*W*H) | 8000mm(L)x8000(W)x1800(H) |

| 8 | Electrical control (abnormal handling) | Abnormal alarm real-time situation is displayed on the touch screen in real time | Use first-line brand controller, 7 inches |

| 9 | Safe operation | Push button start or foot switch start | And there is a protective door closing detection device, equipped with a photoelectric protection device to ensure the safety of the operator. Equipped with emergency stop and zero reset device |

- Commonly used standard parts

| Device name | Optional brand | Remarks (origin) |

| PLC | Mitsubishi, Panasonic, Siemens | China |

| Touch screen | Panasonic, Weilun | China |

| Pneumatic components | SMC/Airtac | Japan/Taiwan,China |

| Solenoid valve | SMC/Airtac | Japan/Taiwan,China |

| Screw rod, linear guide rail | Hiwin/THK | Taiwan,China |

| Linear module | Hiwin/CCM | China |

| Servo motor | Panasonic | Japan |

| Stepper motor | Panasonic | Japan |

| Fiber optic sensor | Keyence/Panasonic | Japan |

| Photoelectric sensor | Keyence/Leuze | Japan/Germany |

| Command electrical appliances | JINHONG | China |

| Low voltage electrical appliances | CHNT | China |

| Switching power | MW | China |

| Mechanical standard parts | NSK、THK、NTN、HIWIN、MISUMI | Japan/China |

中文

中文

English

English