Home appliance parts automation - 15-minute washing timer automatic assembly line >>>

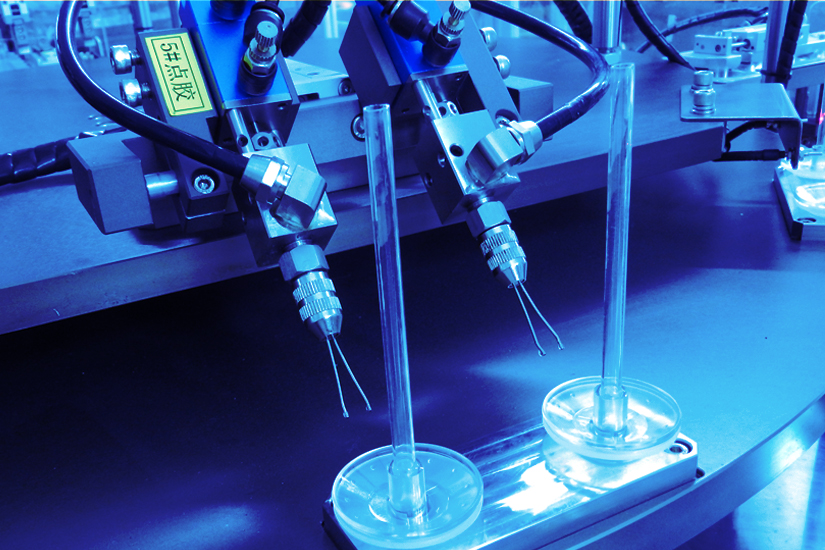

Process: This equipment is used for automatic assembly of washing machine conversion switches. The housing, reed, cam, spindle, sealing ring and screws are automatically fed by a vibration plate. The working process is as follows: put on the base → put on the static reed → put on the moving reed → put on the cam → put on the spindle → put on the upper cover → dispense glue → put on the sealing ring → flip → install the plate reed → add grease → put on the lever → screw → unload the line.

1、First assembly completed | 2、Second assembly completed |

|---|---|

The process includes: manual base installation, product dust removal, upper and lower cams, second wheel installation, second wheel oiling, second wheel shaft gear assembly, second wheel combination flipping, second wheel shaft installation, and second wheel installation. |

Including the following processes: installing the balance wheel, installing the escape wheel, oiling the escape wheel, installing the fourth wheel, installing the upper cam, installing the time wheel, and oiling the time wheel. |

3D Top View |

3D Top View |

3、The third assembly is completed | 4、The fourth unit is assembled |

Including processes: manual lever installation, manual wire placement, manual cover placement, screw 1, screw 2, spring winding, automatic unloading |

The process includes: manual turning over and loading, sealing ring installation, positioning pin riveting, knob riveting, and automatic unloading. |

3D Top View |

3D Top View |

- Machine related parameters

| NO | Project Name | Parameters | Notes |

| 1 | Assembly cycle | 4 seconds/time | 900pcs/H |

| 2 | Assembly tooling | Specialized | |

| 3 | Assembly accuracy | Error less than 0.05MM | No damage to the product during assembly |

| 4 | Monitoring mode | Multiple monitoring modes | Parameter setting, height value, position value |

| 5 | Control mode | Automatic/manual conversion | All actions of the equipment should have automatic and manual mode selection functions, and the operation panel and installation position should be reasonably designed. |

| 6 | Operation mode | Human-machine cooperation | Some workstations require manual operation |

| 7 | Equipment dimensions | (L*W*H) | 8000mm(L)x8000(W)x1800(H) |

| 8 | Electrical control (abnormal handling) | Abnormal alarm real-time situation is displayed on the touch screen in real time | Use first-line brand controller, 7 inches |

| 9 | Safe operation | Push button start or foot switch start | And there is a protective door closing detection device, equipped with a photoelectric protection device to ensure the safety of the operator. Equipped with emergency stop and zero reset device |

- Commonly used standard parts

| Device name | Optional brand | Remarks (origin) |

| PLC | Mitsubishi, Panasonic, Siemens | China |

| Touch screen | Panasonic, Weilun | China |

| Pneumatic components | SMC/Airtac | Japan/Taiwan,China |

| Solenoid valve | SMC/Airtac | Japan/Taiwan,China |

| Screw rod, linear guide rail | Hiwin/THK | Taiwan,China |

| Linear module | Hiwin/CCM | China |

| Servo motor | Panasonic | Japan |

| Stepper motor | Panasonic | Japan |

| Fiber optic sensor | Keyence/Panasonic | Japan |

| Photoelectric sensor | Keyence/Leuze | Japan/Germany |

| Command electrical appliances | JINHONG | China |

| Low voltage electrical appliances | CHNT | China |

| Switching power | MW | China |

| Mechanical standard parts | NSK、THK、NTN、HIWIN、MISUMI | Japan/China |

中文

中文

English

English